Background and overview[1]

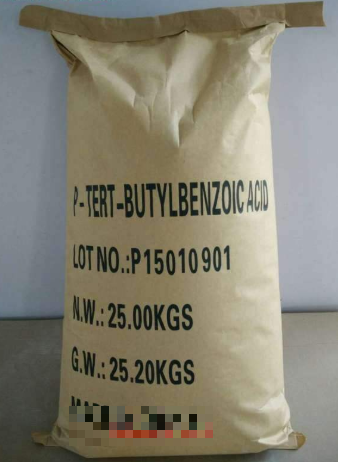

P-tert-butylbenzoic acid (PTBA) is colorless needle-shaped crystals or crystalline powder. It is a derivative of benzoic acid and an important organic synthesis intermediate. Its main uses are: (1) used to produce alcohol Improver of acid resin; (2) Used as cutting oil and lubricating oil additives; (3) Used as polypropylene nucleating agent; (4) Its barium salt, sodium salt, zinc salt, etc. can be used as polyvinyl chloride Stabilizer; (5) used as food preservative; (6) regulator of polyester polymerization, etc.

Laboratory research on this product began in the 1930s. Currently, products have been put on the market in the United States, Japan, Germany and other countries, but they have not yet been put into production in China. As a result, domestic users, especially polyvinyl chloride and polyvinyl chloride, have All the PTBA required for the ester industrial system is imported, so the development and research of this product has broad development prospects.

Preparation[2]

A preparation process for p-tert-butylbenzoic acid, which is characterized by: including the following steps:

(1). Add toluene, isobutylene and concentrated sulfuric acid into the reactor for alkylation reaction to obtain crude p-tert-butyltoluene. The temperature of the alkylation reaction is 20-24°C and the time is 10-12 hours, and then distill the crude p-tert-butyltoluene to obtain p-tert-butyltoluene;

(2). Add the prepared p-tert-butyltoluene and composite catalyst into the reactor and introduce oxygen to carry out oxidation reaction to obtain crude p-tert-butylbenzoic acid. The reaction temperature is 110-180°C and the time is 12-24 hours, the composite catalyst is composed of cobalt acetate and bromide, which are added to the reaction kettle respectively;

(3). Cool and crystallize the crude p-tert-butylbenzoic acid, centrifuge and spin dry, wash with p-tert-butyltoluene, then add the crude p-tert-butylbenzoic acid to toluene, raise the temperature to dissolve, and then add activated carbon , diatomaceous earth for decolorization, then cooling, crystallization, and centrifugation to obtain fine p-tert-butylbenzoic acid;

(4). After the fine p-tert-butylbenzoic acid is washed with water, washed with toluene, centrifuged and dried, the finished product of p-tert-butylbenzoic acid is obtained.

Apply[3-4]

P-tert-butylbenzoic acid is an organic synthesis intermediate, mainly used as polypropylene nucleating agent, polyvinyl chloride heat stabilizer, metal processing cutting and lubricating oil additives, antioxidants, alkyd resin modifiers, It has various special functions such as flux and dye; it is the main raw material for the production of methyl p-tert-butyl benzoate. Methyl p-tert-butyl benzoate is an organic synthesis intermediate and is mainly used as UV absorber and new coating additive. tert-butylbenzoic acid plays an increasingly important role in the development of the national economy. CN201810391302.4 discloses the preparation of methyl p-tert-butyl benzoate, in which a composite catalyst is first used to oxidize p-tert-butyltoluene in the air to obtain p-tert-butyl benzoic acid, and then replaced by p-toluenesulfonic acid Traditional concentrated sulfuric acid is used as a catalyst to carry out an esterification reaction to obtain methyl p-tert-butyl benzoate; at the same time, the present invention adopts a special treatment process for the preparation of methyl p-tert-butyl benzoate. Yield and product purity. At the same time, the steamed methanol, extracted water phase and catalyst are processed and reused, which not only greatly reduces the cost of raw materials, but also has important environmental significance.

CN201510282376.0 discloses a method using phenylethyl ether and toluene as starting materials, and synthesizing avobenzone through alkylation, oxidation, esterification, acylation and condensation reaction. In the oxidation reaction, potassium permanganate oxidant is divided into 6 It is put into the reaction system for the first time, which prevents the occurrence of thermal decomposition and deacidification of potassium peroxide, and improves the yield of the reaction; the esterification reaction uses methylsulfonic acid as the catalyst, and the mole ratio of p-tert-butylbenzoic acid and methanol The ratio was 1:7, and the reflux reaction was carried out for 8 hours. Methanol was added for the reaction in two stages, which solved the problem of being unable to separate water during the reaction. In the acylation reaction, phosphotungstic acid was used as a catalyst, which improved the selectivity of the reaction. The post-processing of the reaction is simpler, the reaction yield is also improved, and the phosphotungstic acid can be recycled, which saves costs and is more conducive to industrial production.

Main reference materials

[1]Xu Ying. Synthesis of p-tert-butylbenzoic acid[J]. Journal of Liaoning Normal University (Natural Science Edition), 2006(02):99-101.

[2]CN200910145003.3 Preparation process of p-tert-butylbenzoic acid

[3]CN201810391302.4 Preparation of methyl p-tert-butyl benzoate

[4]CN201510282376.0 A synthesis method of avobenzone

微信扫一扫打赏

微信扫一扫打赏