Background and overview[1]

4-Fluorophenylacetic acid is an organic synthesis intermediate and pharmaceutical intermediate. It can be used in laboratory research and development processes and chemical and pharmaceutical research and development processes. It can play an irreplaceable role in the synthesis of pharmaceuticals, electronic materials, etc.

Preparation[1-2]

Method 1: Preparation of 4-fluorophenyl acetic acid: Add 800 grams of 15% HCl and 250 grams of 4-fluoroaniline into the reaction bottle, heat and stir until dissolved. Cool the temperature to -5~5℃, add 400g methylene chloride, 20g tetramethylammonium chloride and 20g copper chloride. Add dropwise a dichloromethane solution containing 250 g of vinylidene chloride. Maintain the temperature and slowly add an aqueous solution containing 210g sodium nitrite dropwise. The reaction was kept warm for 2 hours. After the reaction is completed, excess nitrous acid is quenched. Dichloromethane was added for extraction and then desolvated to obtain 396.2 g of 1-(2,2,2-trichloroethyl)-4-fluorobenzene. Add 400g of 25% hydrochloric acid to the three-necked flask under nitrogen protection. Heat to 65~75℃. 300g of intermediate 1-(2,2,2-trichloroethyl)-4-fluorobenzene and 50g of dichloroethane were added dropwise. After the dropwise addition is completed, the reaction is kept warm for 8 hours. The reaction is complete. The cooling system was added dropwise to ice water to quench. Filter, wash with water, dry and recrystallize with toluene to obtain 175.6g of pure 4-fluorophenyl acetic acid, with HPLC purity greater than 99wt%.

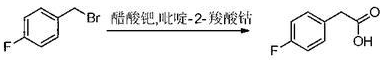

Method 2: Add 312ml of methanol, 0.55g of cobalt pyridine-2-carboxylate, and 1.37g of palladium acetate into the autoclave reaction kettle, stir for 5 minutes to dissolve the catalyst, replace the air in the kettle with CO three times, and raise the temperature. to 180°C, and pour in CO until the pressure rises to 1.5MPa. Within 1 hour, simultaneously add 57.8g (0.4mol) p-fluorobenzyl and 160g (1.2mol) 30% NaOH dropwise into the reaction kettle. After 5 hours of reaction, cool to room temperature, remove methanol by distillation under reduced pressure, filter out the catalyst, add 30% hydrochloric acid to adjust the pH to 1, filter and dry to obtain 4-fluorophenyl acetic acid, with a purity of 99.40% and a yield of 84%. .

Main reference materials

[1] CN201710170399.1 Preparation method of fluorophenylacetic acid

[2]CN201710648619.7 Preparation method of phenylacetic acid compounds

微信扫一扫打赏

微信扫一扫打赏