On April 6, the 2023 Shanghai Global Investment Promotion Conference was held at the World Expo Center.

The conference focused on releasing a batch of achievements in attracting investment and attracting talents. Since the beginning of this year, the city has signed a total of 353 major industrial projects worth more than 100 million yuan, with a total investment of 225.4 billion yuan. Recently, it has sorted out 168 major investment contracted projects with a total investment of 327 billion yuan, of which 26 are large-scale and high-level representatives. The project was signed at the conference site, with a total investment of 67.4 billion yuan.

At the 2023 Shanghai Global Investment Promotion Conference, there are 2 major industrial projects involving the chemical industry zone. Ma Jing, Secretary of the Party Group and Director of the Chemical Industry Zone Management Committee, signed a 750,000-ton/year PDH and hydrogen utilization supporting project with Chen Dasheng, vice president of Shanghai Huayi Holding Group Co., Ltd., and signed a contract with the Hongkou District Government and Beijing Shougang Langze Technology Co., Ltd. signed a strategic cooperation framework agreement.

Key project plan

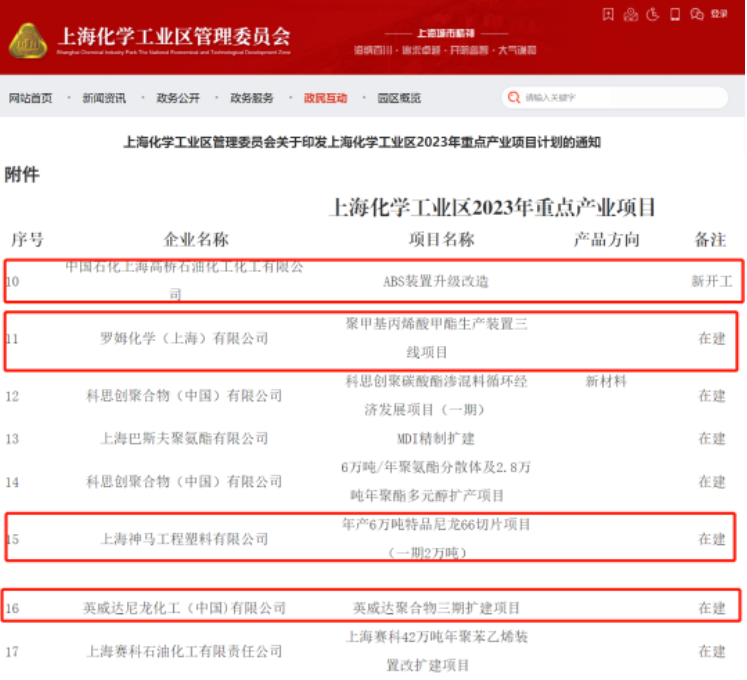

In addition, the Shanghai Chemical Industry Park Management Committee recently announced the 2023 key industry project plan of the Shanghai Chemical Industry Park. Involving 26 projects with an investment of 25.57 billion yuan, including Rohm Chemical PMMA third-line project, Shanghai Shenma Engineering Plastics 60,000 tons special nylon 66 chip project (first phase 20,000 tons), INVISTA Polymer Phase III expansion project, These projects are all projects under construction.

On November 25, 2022, the Chemical Industry Zone held the Nylon Integrated Industry Base Promotion Meeting and Nylon Industry Development Forum to witness the commissioning of the INVISTA Adiponitrile Project, the start of the Nylon 6,6 Expansion Project, and the start of the Shenma Special Nylon Project. The investment intention of Dyne new material innovation industrialization project was signed, and the INVISTA Asia-Pacific R&D Center was officially put into operation. Among them, INVISTA Nylon Chemical Adiponitrile

After the (ADN) production base is officially completed in Shanghai Chemical Industry Park (SCIP), its adiponitrile production capacity will exceed 400,000 tons per year.

Rohm Chemical PMMA Expansion Project

On July 12, 2022, the ROHM Group held the groundbreaking ceremony for the expansion project of the PLEXIGLAS (polymethyl methacrylate, PMMA) molding compound factory in Shanghai. This move aims to expand the global production capacity of PLEXIGLA Special Molding Compounds and better customize PMMA products for customers. The expanded Shanghai plant is expected to be completed and put into operation in the second quarter of 2023.

It is learned from the environmental impact assessment documents that in order to cope with changes in the raw material and product markets, Rohm Chemical intends to carry out technical transformation or capacity expansion through multiple sets of equipment in the whole plant of this project. Among them, the technical transformation of MMA equipment is proposed. After the technical transformation, the total production capacity of MMA can reach up to 127,000 tons/year, and at the same time, a PMMA production line will be added, with a production capacity of 20,000 tons/year. The total investment of the entire reconstruction and expansion project is 240 million. The project implements phased construction and phased acceptance. Among them, the first phase of the project includes the technical transformation of the MMA device and the expansion of the PICOC line, and the second phase includes the technical transformation of the BUMA device and the KP3 line.

The following are the main contents of the project construction:

I) Technical transformation of MMA unit: use the surplus of the existing MMA production and installation of double refining towers, and carry out rectification of purchased MMA, so as to achieve the purpose of producing MMA products through different raw materials. After the technical transformation, the total output of MMA will not exceed the output approved by the EIA of 127,000t/a.

2) Technical improvement of BUMA device: increase its function of producing new product EHMA. After the technical transformation, the annual production time of the BUMA plant remains unchanged at 8000h/a; the full-load capacity of the new product is 12,500t/a, and the full-load capacity of the original BUMA product does not exceed the approved production capacity of 20,000t/a.

3) KP3 line: On the basis of the existing two PMMA production lines, a new PMMA production line will be built, namely KP3 line, with a design capacity of 20,000t/a. After the expansion, the total production capacity of the KP plant will increase from 40,000t/a to 60,000t/a.

4) PICOC line capacity expansion: The existing 1 PMMA coloring test line PICOC line of the PC device is converted into a formal production line, and the annual operation time is extended to 8500h/a (288h is cleaning time) to realize capacity expansion. After the completion of the project, the designed production capacity of the PICOC line will be 2874t/a, and the total production capacity of PC equipment will increase to 25,874tla.

Shenma Special Nylon Project

As mentioned earlier, at the Nylon Integrated Industry Base Promotion Meeting and Nylon Industry Development Forum, the Shenma Special Nylon Project started! On the evening of March 10, 2022, Shenma Industrial Co., Ltd. issued a capital increase announcement. The capital increase of this time is 51.824 million yuan, which is mainly used for the annual production of 60,000 tons of special nylon 66 chips of Shanghai Shenma Engineering Plastics Co., Ltd. (Phase 2 million tons) project construction. The total investment of the project is 306.08 million yuan, and the construction period is 24 months.

In terms of project location selection, Shanghai Shenma Engineering Plastics Co., Ltd. selected the project and site adjacent to the INVISTA Hexamethylenediamine Factory, and the main raw material Hexamethylenediamine can be directly supplied nearby.

Gaoqiao Petrochemical ABS Plant Upgrading Project

At the end of March, Gaoqiao Petrochemical’s ABS plant upgrade project was accepted for environmental impact assessment. Caojing Plant of Gaoqiao Petrochemical has built a 200,000-ton/year phenol acetone plant, a 100,000-ton/year styrene-butadiene rubber plant and a 200,000-ton/year ABS plant. Based on the analysis and judgment of the ABS product market and the evaluation of on-site production equipment, Gaoqiao Petrochemical plans to increase the production capacity of ABS products to 300,000 tons/year. There are 3 production lines in the existing ABS device, and the ABS production technology of American DOW Chemical Company is selected. The production capacity is increased to the designed production capacity of the device. The full-load production capacity of the daily production line is 75,000 tons/year. After completion, the total production capacity of the four production lines will be 300,000 tons/year.

The total investment of this project is 780 million yuan, and the construction period is 8 months. It is expected to start in May 2023 and complete in January 2024. Global Polyurethane Network-Service Polyurethane Enterprises, Polyurethane Price Quotes, Polyurethane Raw Material Prices, Polyurethane Foam, Polyurethane Insulation Pipe, Buy Polyurethane (puworld.com)

微信扫一扫打赏

微信扫一扫打赏