● ISCC PLUS certification: mass balance method, production with renewable raw materials

● Customers can choose more sustainable antioxidants without compromising functionality

● Initial certification includes some plastic additives produced at BASF’s production sites in Switzerland and the United States

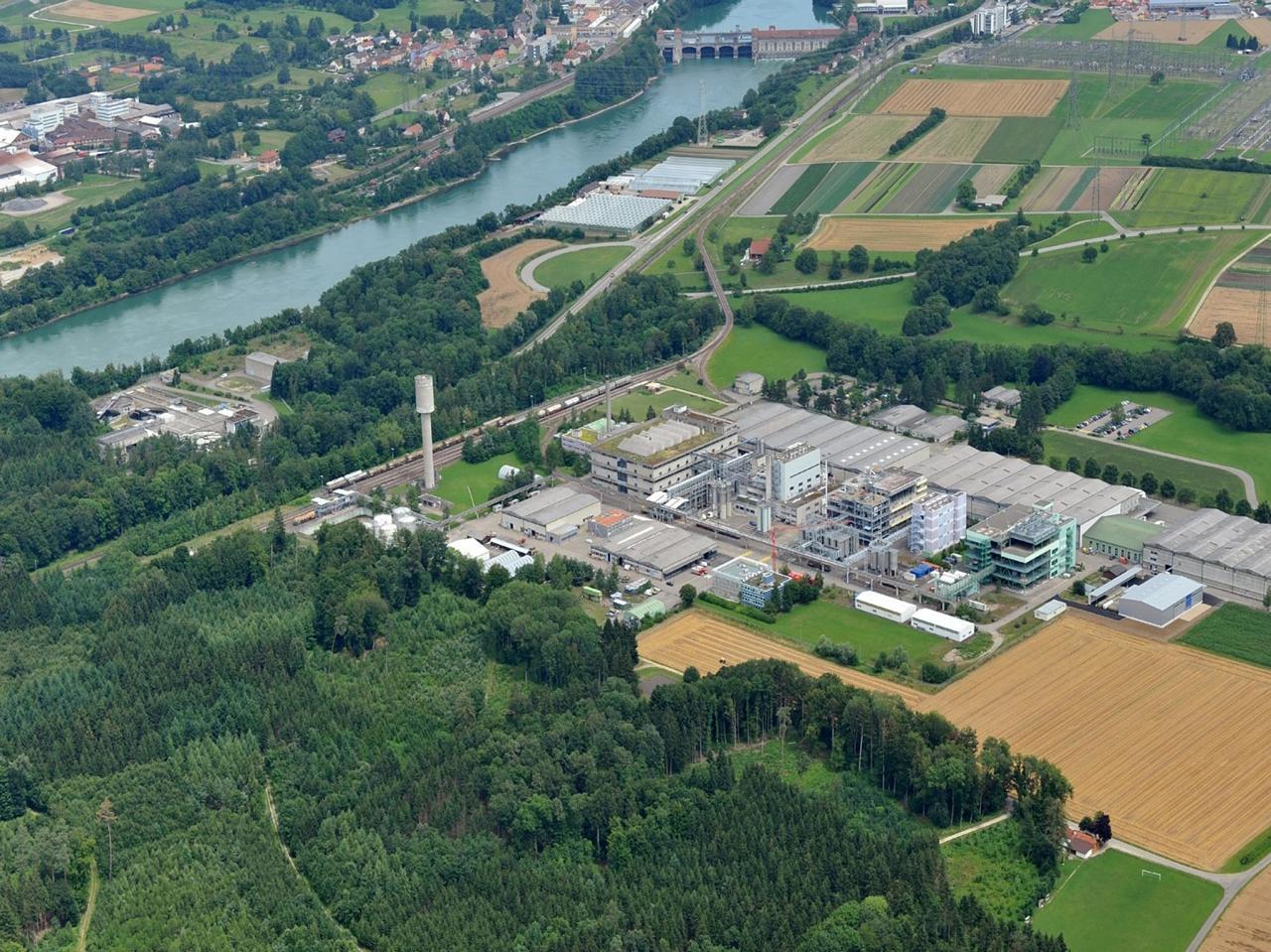

BASF announced today that certain grades of plastic additives produced at its production sites in Kesten, Switzerland and McIntosh, Alabama, USA have received the International Sustainability and Carbon Certification (ISCC) PLUS. The certification will allow BASF to reduce the carbon footprint of its products (PCF) by producing and supplying more sustainable core plastic additives using renewable raw materials in a mass-balanced manner.

ISCC PLUS certification covers the entire value chain and ensures the use of renewable materials. It is an accreditation process for an internationally recognized mass balance method.

The certification paves the way for BASF to offer its plastic additives customers mass balance certificates for certain products. As part of mass balance certification, the chain of custody from the input of renewable raw materials to the final sale of the product with a sustainability claim must be demonstrated. The company’s production sites in Switzerland and the US are two pilots for the certification as part of the global implementation.

Achim, Senior Vice President Plastic Additives, BASF

Dr Sties said: “We are the first plastics additive supplier to offer a range of biomass balance certified antioxidants, an extension of our VALERAS® range. Our customers can now choose from more sustainable antioxidants. Although these antioxidants are produced using more responsibly sourced renewable materials rather than fossil resources, this does not compromise their high efficacy performance. As we continue to create new value for plastics with our customers and partners, we focus on Drive innovation and make a significant contribution to sustainable development.”

微信扫一扫打赏

微信扫一扫打赏