Background and overview[1]

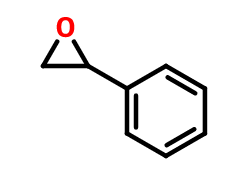

Styrene oxide, also known as phenyl ethylene oxide or 1,2-ethylene oxide, is a colorless liquid with an aromatic odor, with a boiling point of 194°C, difficult to dissolve in water, but easily soluble In organic solvents such as methanol, ether, carbon tetrachloride, benzene, acetone, etc.

It is an electrophilic compound that can covalently bind to nucleophilic groups on nucleic acids or proteins such as sulfhydryl groups, imidazole groups, carboxyl groups, amino groups, etc.

Styrene oxide is an important fine chemical for post-processing of styrene. It is mainly used in spices, pharmaceutical industry, and organic synthesis. It can also be used as epoxy resin diluent, UV-absorber, and flavoring agent. This substance has irritating and sensitizing effects on the skin. It has also been confirmed that it can interact with DNA and may be genotoxic or carcinogenic. Some countries have formulated MRLs value standards for styrene oxide in related products to reduce the risk of material exposure as much as possible. Currently, styrene oxide has been included in GADSL (Global Automotive Declared Substance List). Toyota Motor’s MRLs value standard for this substance is 0.1% (i.e. 1000mg/kg).

Apply[2-3]

CN201710429827.8 provides a preparation method of mandelic acid. The preparation method includes: styrene oxide is hydrated under NY series catalysis to prepare phenylglycol, and phenylglycol is supported on activated carbon with a Pd-Au catalyst Under the action, air is introduced to selectively oxidize mandelic acid to generate mandelic acid. The preparation method is characterized in that the raw materials used are mainly styrene oxide, NY series catalysts and activated carbon supported Pd-Au catalysts. The preparation method of mandelic acid of the present invention is simple, the raw materials are cheap and easily available, the preparation process is simple, the conditions are mild, and the product yield and purity are high.

CN94112147. , prepare β-phenylethyl alcohol through catalytic hydrogenation at a reaction temperature of 25~50℃ and a pressure of 1.0~5.0MPa. This process has the advantages of good product quality, high yield, and few side reactions.

References

[1][China invention, China invention authorization] CN201410709557.2 A gas chromatography-mass spectrometry analysis method for styrene oxide

[2]CN201710429827.8 A method for preparing mandelic acid from styrene oxide

[3]CN94112147.X Preparation of β-phenylethyl alcohol by catalytic hydrogenation of styrene oxide

微信扫一扫打赏

微信扫一扫打赏